| HDF | Block Board |

| Raw Material HDF is High Density Fiberboard and is similar to particle board and medium-density board but it is much denser and stronger. It is made by compressing wood fibers mechanically.

Style/Finishing HDF is a much stronger board compared to MDF and it gives a smooth and uniform surface wherever it is applied. HDF does not have any grain and it can be finished by applying paint on it. If you want wood grain finishing then you would need to put a veneer or teak ply on the HDF board Maintenance To protect HDF the steps below should be taken.

Advantages

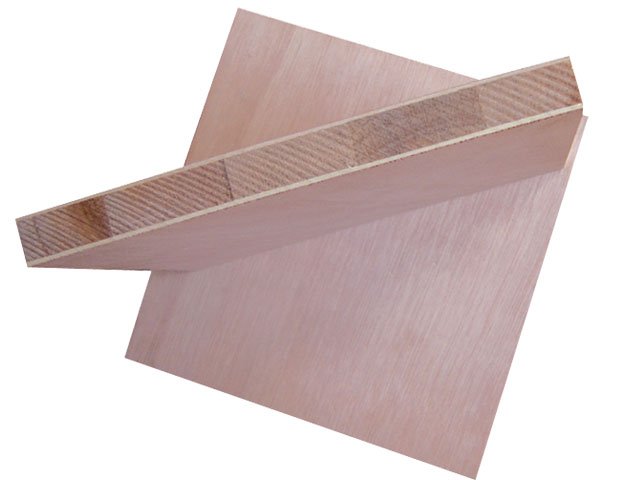

Disadvantages HDF is the best board when compared with particle board and MDF. Still a lot of carpenters prefer wood block board compared to HDF as they are more confident about the nail holding capabilities of natural wood whose blocks are used to build the block board | Raw Material Block board is a type of board made by wooden pieces inserted between ply of hardwood which bonded together under a high pressure and temperature.

Style/Finishing Block board does not have any grain and it can be finished by applying paint on it. If you want wood grain finishing then you would need to put a veneer or teak ply on the block board Maintenance To protect block board the steps below should be taken.

Advantages

Disadvantages Comparatively expensive. |

HDF v/s Block Board

Labels:

wood